15 Wildfire Rd Maddington, WA 6109

Home » trenchless » Horizontal Directional Drilling Tools » Backreamers » Fly Cutter

Skip to the content

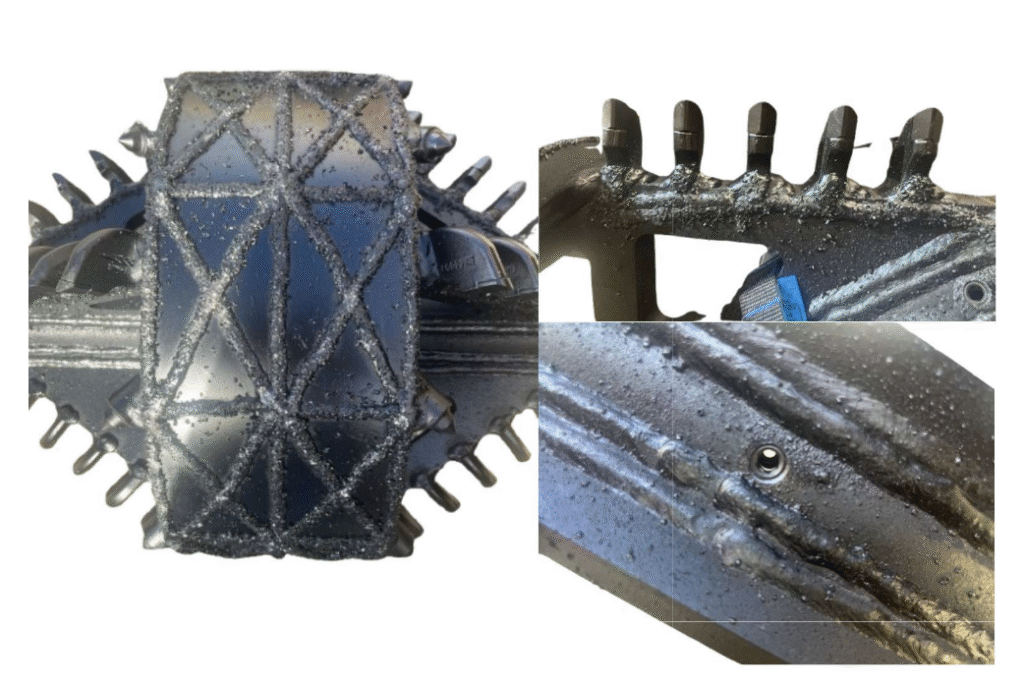

Our Fly Cutter Back Reamers are engineered to tackle mixed ground conditions, including clay, abrasive soils, and even cobble-laden formations. They are designed with winged extensions and carbide shark teeth that provide a powerful cutting action while efficiently displacing cuttings to prevent clogging or hole instability.

Our Fly Cutter Reamers are particularly effective in challenging terrain where traditional compaction reamers may struggle. Their open body and winged flutes allow for large cobbles and dense soil to pass freely, while maintaining consistent mixing and spoil evacuation.

The Fly Cutter features carbide teeth mounted to high-torque arms that shred through tough soils and light rock as it’s pulled back through the borehole.

• The conical body supports smooth cutting action

• Large openings between wings allow unrestricted flow of drilling fluids and spoil

• Aggressive cutting structure prevents build-up and blockage

This allows the reamer to keep pace with your forward progress,

increasing operational efficiency.

Each Fly Cutter Back Reamer is built with high-strength steel, carbide shark teeth, and additional tungsten carbide hardfacing for enhanced wear resistance. A central stabilising ring helps guide the reamer and ensures a smooth, round borehole, reducing pipe drag and product damage during pullback. Our Fly Cutter Reamers are designed with rebuildability in mind, making them a cost-effective long-term solution for your HDD operations.

| Fly Cutter | |

| Cut Size | Part # |

| Fly Cutter 250mm Diameter | RF250 |

| Fly Cutter 300mm Diameter | RF300 |

| Fly Cutter 350mm Diameter | RF350 |

| Fly Cutter 400mm Diameter | RF400 |

• Carbide Shark Teeth for aggressive ground engagement

• Large Winged Flutes for spoil flow and mixing action

• Additional Tungsten Carbide Hardfacing for extended wear life

• Exta Wide Stabilising Ring to maintain borehole roundness

• Balanced Wing Design helps maintain directional control and stability — ideal for pushing back in the event the package becomes stuck in the borehole

Copyright © 2026 No Dig Equipment. All Rights Reserved.